In part two of my three-part series on how to eliminate the drag on your business that’s holding you back, we’ll talk about core processes.

A core process is central to delivering the value proposition to the customer and running the organization. An example might be the product development process, or onboarding new customers, or pricing approval process.

The primary goals of core processes are to 1) ensure quality and 2) increase the capacity of the organization. Sometimes these processes break down and do not optimize capacity. When core processes inside an organization break down, they profoundly impact people and productivity. Sometimes, they can seem too big and unruly to fix, so we create workarounds or accept the problem.

What a tragedy and a huge missed opportunity for an organization!

Improving a broken core process can significantly impact the team’s attitude and strengthen its work capacity.

Process improvement is an entire discipline, and it can get complicated. By following my guide, you can make considerable improvement without hiring a consultant or upend the whole organization.

Process Improvement vs. Business Process Redesign

One distinction I’d like to make clear is the difference between process improvement and business process redesign. Process improvement is enhancing an existing process awhile business process design (BPR) is a complete tear-down and rebuild of the process. I’m focusing here on process improvement.

Here’s why. You may want to redesign your process, but initially, I’d advise against it.

Redesigning a process can be transformative, but it is disruptive, and it can take a long time. During a recovery phase, I don’t recommend that sort of disruption. It’s costly, and it’s a distraction. We always underestimate how much of a distraction BPR will be. I would offer that you focus the team on a process improvement, make the changes, and reap the rewards. If a redesign is still needed, it will be easier to do because you’ll have the momentum from the process improvement, and you shouldn’t have as much resistance from the organization.

So let’s talk about what a process improvement would entail.

Process Improvement Guide

Identify that ONE core process that you want to improve, the one that will have the most impact on increasing capacity and eliminating drag on your organization. You’ll then want to get a team of 7-10 cross-functional representatives who will control the process and participate in it. Here’s an overview.

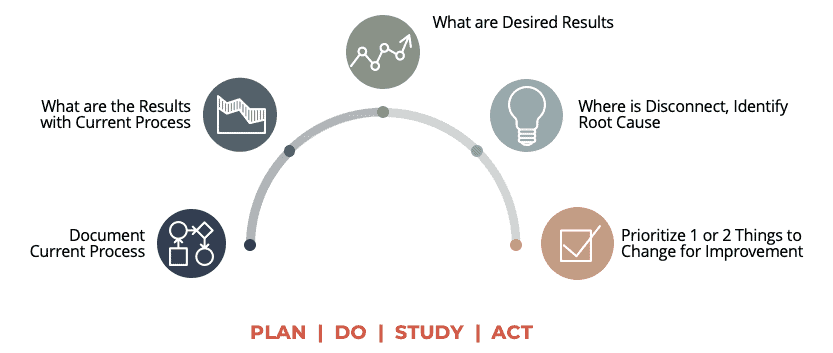

Document Current Process

Document the current process (you can do a simple process map, nothing complicated), the current process, who is involved, and how long things take.

Current Results

What are the current results – how do you measure this process’s effectiveness, and what are those metrics of the current process? What do the customers think about the process?

Desired Results

What do you want the results to be – what are the metrics, timelines, and costs you would like to have?

Root Cause Analysis

Where is the disconnect – brainstorm what might be wrong with the process. What might be the root cause of the disconnect? I’ve provided two tools that I find helpful in root cause analysis: one is the fishbone, and the other is 5 whys. You can download these two tools below.

Prioritize Improvements

Prioritize the one or two things that need to be fixed based on the root cause and determine how you might fix it.

Once you have an improvement idea, do the PDSA Cycle:

- Plan: Identify the problem or the issue. Perceive the desired outcome. Gather the data.

- Do: Conduct the action. Make improvements. Implement the changes.

- Study: Review the actions, improvements, and changes. Are they all positive? Were there any negative consequences?

- Act: Document the improvements. Lock in the changes. If there were any negatives, conduct the planning process again.

Download two very useful root cause analysis tools below.

Download FREE Root Cause Tools

I’ll send you The 5 Whys and Fishbone Root Cause Analysis Tools to help you prioritize process improvements.

This process does not need to be complicated, and in fact, it shouldn’t. There’s a reason people let broken processes remain unchecked regardless of the heartache and problems they cause. It’s easy to try to do too much and end up not changing anything.

That’s why I recommend you don’t try to change everything and optimize everything. It’s not a redesign; it’s an improvement. Free up some capacity for the organization to execute focus few, and you can come back to the next round of progress when you are well on your way to recovery.

In the next post, I’ll share some meeting techniques that will transform the way you work.

Stay safe and be well.

Lead Your Business Back to Growth & Profitability

In this training course, I’ll teach you my Return To Growth model to help you identify your best opportunities that leverage your existing capabilities and get laser-focused on what you need to do to put your business in the best position to return to growth and thrive as quickly as possible!